Recently I have been experimenting with ImagOn Film for intaglio plate making. ImagOn plate making is tough process to master, but it has some advantages over SolarPlate, including cost (about $0.02 per square inch vs $0.20 per square inch for SolarPlate) and the possibility of making really large plates. ImagOn is less forgiving than SolarPlate, so I am ramping up slowly.

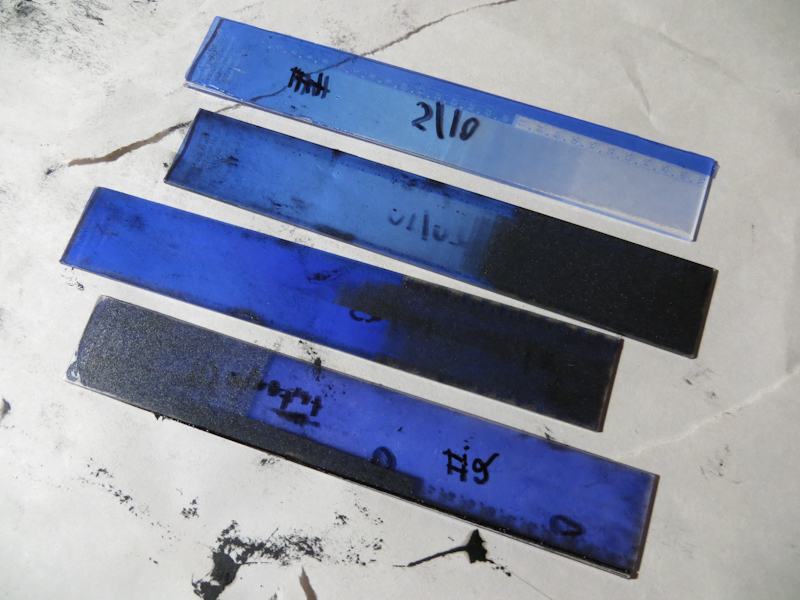

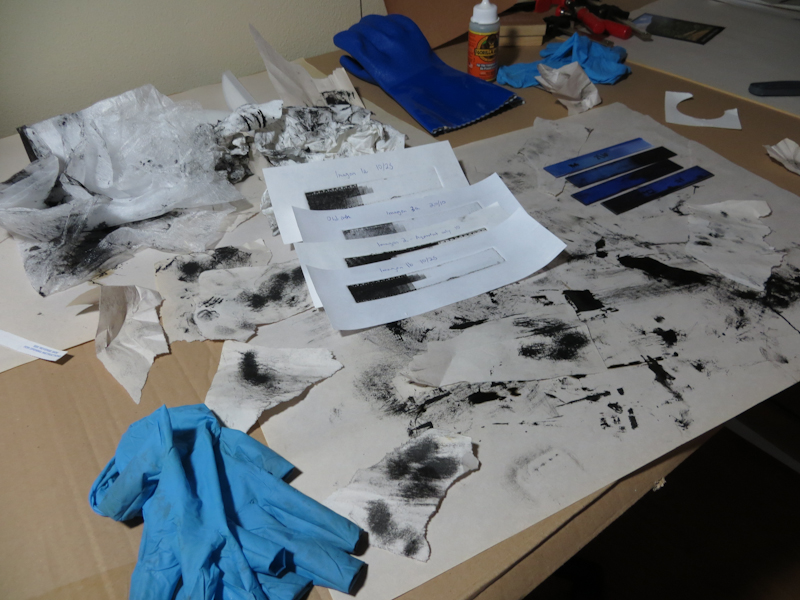

As with SolarPlate, my first goal was to come up with a repeatable process from exposure to development to printing. This post shows my progress in determining the correct exposure.

My main challenge so far has been to get an adequate black from just the aquatint screen. The blacks that I have been able to achieve so far are not nearly as saturated as those from my SolarPlate tests. My general impression is that my ImagOn plates have less etching than my SolarPlates. This may be because of a problem in my process or it may just be an inherent property of ImagOn to which I will have to adapt. More experiments will give me clues.

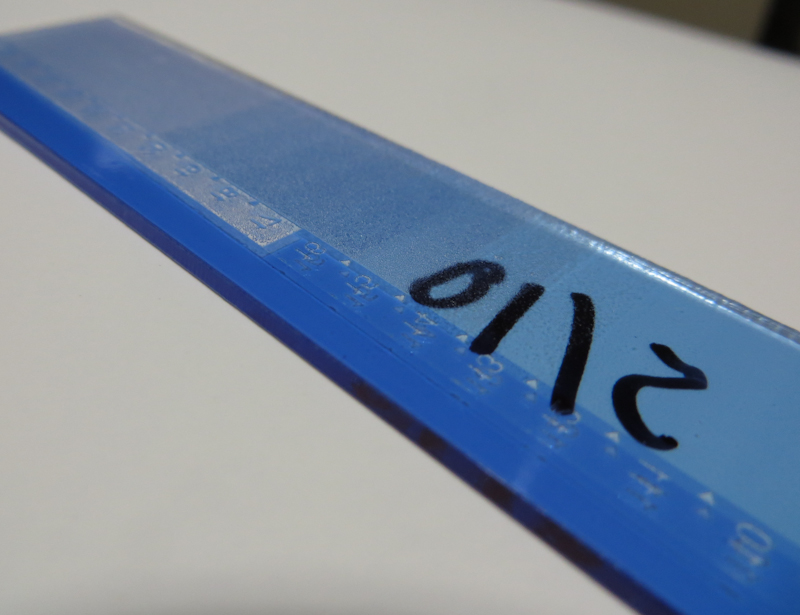

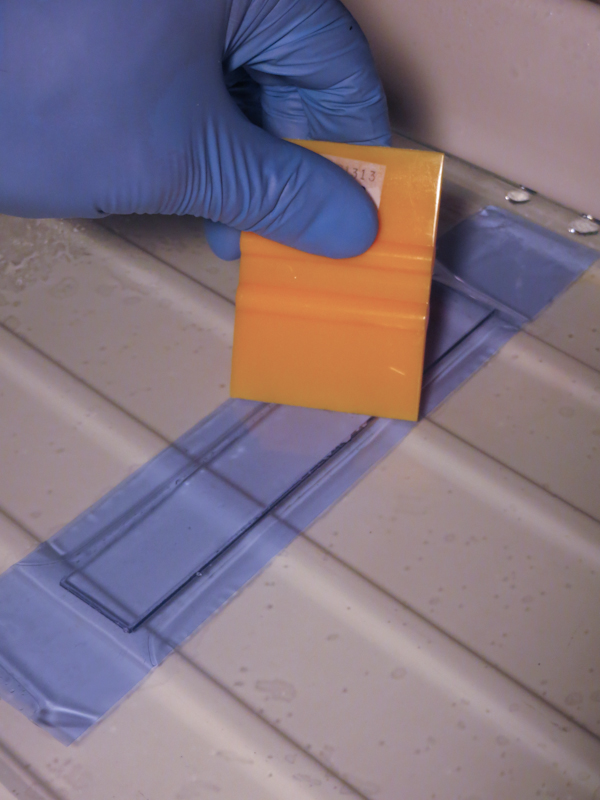

ImagOn is a a film consisting of a 0.002″ thick layer of photopolymer emulsion sandwiched between two protective layers of plastic. The first step in making an a plate with ImagOn is to laminate the emulsion to a metal or plastic plate. The process is easy, involving water and a squeegee, but it must be carried out away from any sources of ultraviolet light.

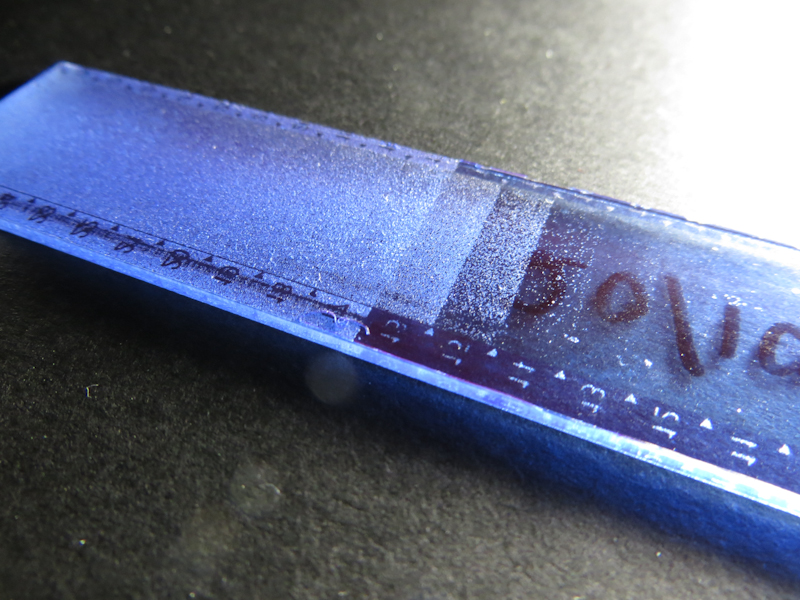

One of the differences between ImagOn and SolarPlate is the color of the emulsion. This plate uses ImagOn Ultra which is a blue like French Ultramarine. ImagOn HD is green. The emulsion for this plate is laminated to a piece of clear acrylic, giving it a very different appearance from SolarPlate which sits on a an opaque steel plate.