The good news is that I am not actually getting head strikes when printing directly to ImagOn plates. The bad news is that the top surface drive wheels on my Epson 3880 printer are leaving tracks in the ImagOn emulsion.

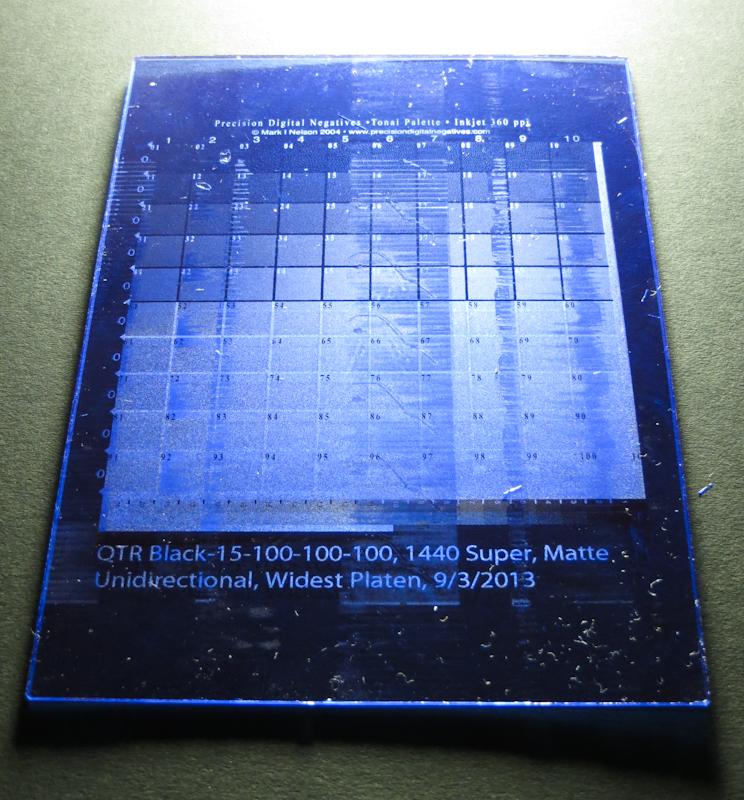

The photo below shows the problem. The worst wheel marks pass through the entire length of the plate, hitting steps 95-97 at the bottom all the way up through steps 5-7 at the top. The drive wheels also put enough sheer force on the emulsion to cause curved wrinkles like the one that passes through the center of step 75. Less severe tracks marks also appear on left and right sides of the plate.

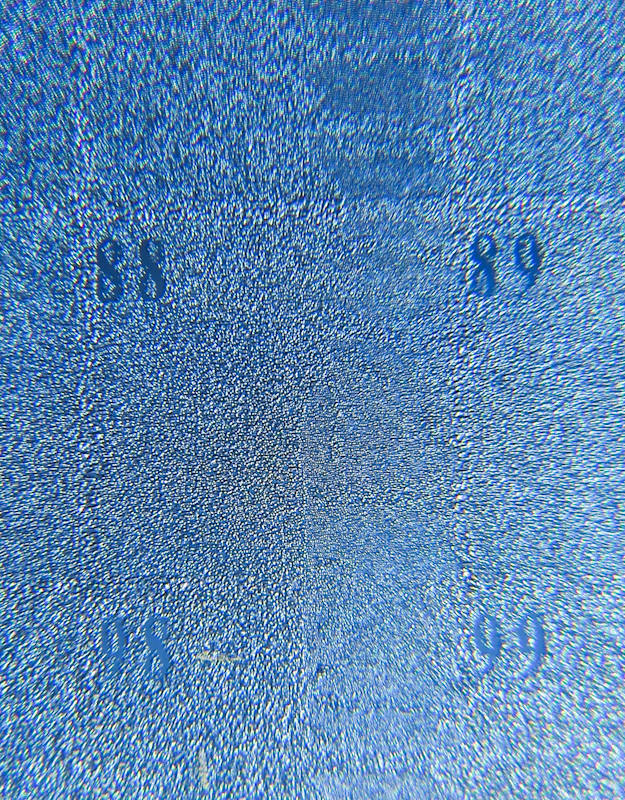

I was hoping these drive marks wouldn’t impact the quality of the matrix, but as with fingerprints, the marks seem to prevent the ink from adhering. Here’s a close up of the narrow track mark on the right side of the plate.

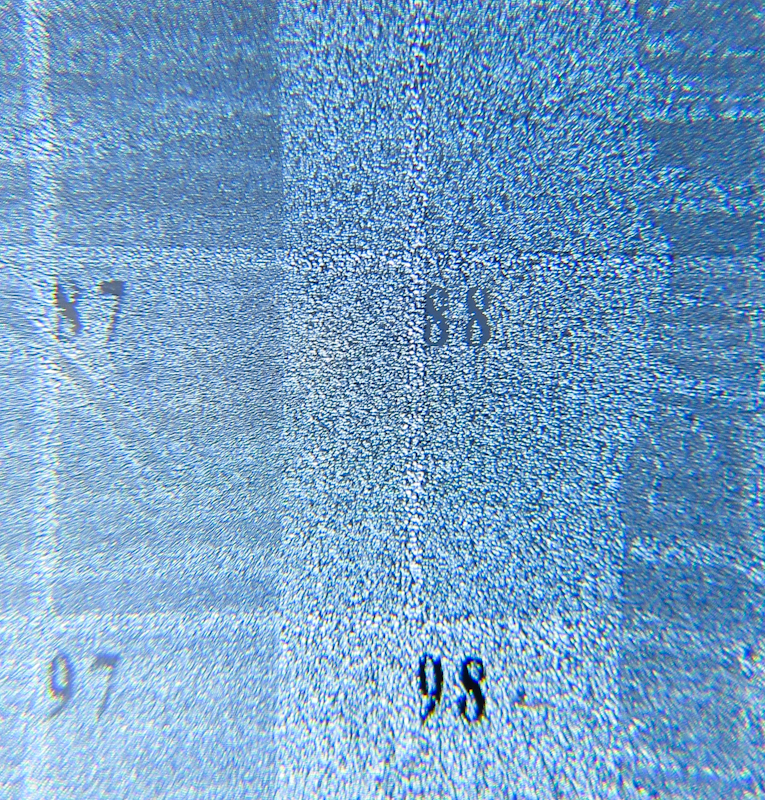

Here’s another close up of the big track mark in the center of the plate:

The impact of these track marks is unacceptable, so hopefully I can find a solution.

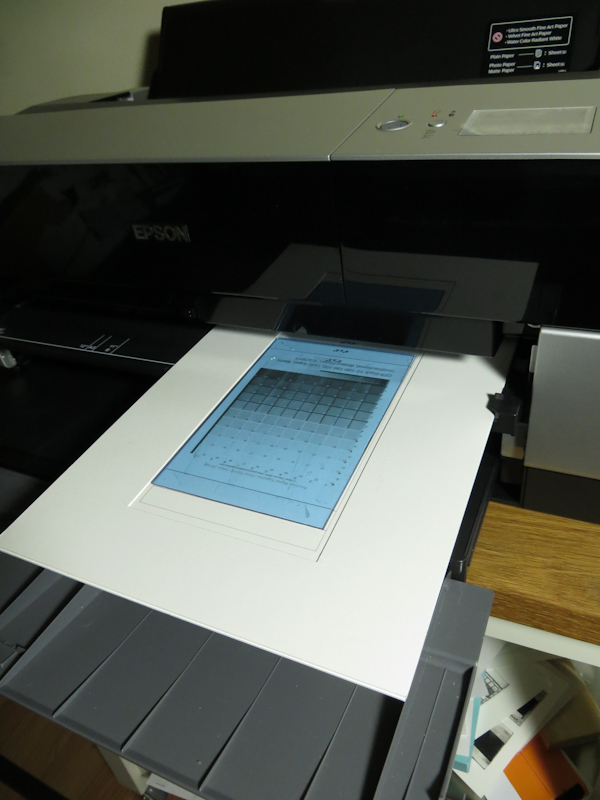

When I first saw the marks, I erroneously concluded that they were due to printer head strikes, and I was able to eliminate them by creating a carrier where the surface of the ImagOn was recessed below the surface of the surrounding window mat. It seems the reason the recessed carrier eliminated the marks is that it prevented the drive wheels from touching the recessed emulsion. The problem with the recessed carrier was that it was too thick to reliably pass through the printer’s front slot.

For the plate in this post, I modified the original carrier design in such a way that the plate was no longer recessed, but the carrier was only about 1mm thick. My hope was to make a carrier that was thin enough to feed reliably, and then use the “Widest” setting for the platen gap to eliminate what I thought were head strikes.

With this larger plate from the new carrier, it is now abundantly clear that the banding I’ve been seeing is due to contact with the drive wheels and not head strikes. I now have a few ideas about why I am getting track marks:

- It is possible that the ImagOn emulsion is so delicate that any contact between the drive wheels and the top of the plate will cause tracks. If this is the case, a thinner, recessed carrier may work, but I may have problems scaling it up to larger sizes because I will always need to leave enough border in the window mat so that there are enough drive wheels in contact with the mat to actually move the carrier through the printer. I might find that my 17″ wide print path needs a 3″ margin on either side, thus reducing my maximum plate width to 11″. If the ImagOn emulsion is really that delicate, one obvious question is how are others successfully doing ImagOn DTP? One thought is that they may be using a different model Epson printer. Some of the higher end printers, like the 4880, use a vacuum suction system so that there is no contact with the top of the print.

- I may have the paper thickness setting incorrect, causing the drive wheels to clamp down much harder than is necessary to move the carrier. Increasing the paper thickness setting might reduce the pressure enough to eliminate the track marks or reduce them to an acceptable level. My evidence for this theory is the wrinkles in the ImagOn. I know from trying to peel ImagOn off of a plate that the emulsion adheres pretty well, meaning that printer would have to generate enormous forces to cause the wrinkles. I don’t think I could make similar wrinkles on a dry plate with my fingernails.

- The design of my carrier, which allows the plate to protrude above the level of the window mat, may be causing the entire force of the drive wheels to hit the emulsion. Perhaps a carrier that put the top surface of the plate flush with the window would divert enough of the pressure to the window mat to reduce or eliminate the track marks.

Now I have another set of experiments ahead of me . . .